회사소개

기술분야

석션 라인

컴프레셔 라인

MCT(머시닝센터)

가공 제조라인

레이져 가공기

절곡, 판금기

| 사업화 품목 | 품목 용도 | 품질 및 가격 경쟁력 |

|---|---|---|

| 건식 석션기 (전 모델) |

개인 치과병원용 |

경쟁사 독일 Durr사 대비 30, 이태리 Cattani사 대비 20 제품단가가 낮고 기존 단점을 개선하여 개발 |

| 대용량 석션기 (Teramax) |

대형병원용 중앙집중식 | 경쟁사 독일 Durr사 대비 50 정도 제품단가가 낮으며, 경쟁사에는 없는 인버터 제어 방식을 적용하여 모터 효율 및 제품 수명 증가 |

| Oil-Free 컴프레서 |

개인 치과병원용 |

경쟁사 독일 Durr사 대비 40, 이태리 Cattani 대비 20의 가격 경쟁력이 있므며, 최신 에어 드라이어에 채택되는 맴브레인 방식을 적용 |

| 건식 석션기 (전 모델) |

개인 치과병원용 |

경쟁사 독일 Durr사 대비 30, 이태리 Cattani사 대비 20 제품단가가 낮고 기존 단점을 개선하여 개발 |

※ 현재 건식 석션은 독일의 Durr Dental, 이탈리아의 Cattani사가 전체 시장의 80%를 점유하고 있으나, 대등한 품질로 모든 공정을 자체 생산하여 경쟁적인 제품을 제공함으로써, 국내시장에서는 이미 선두적인 역할을 하고 있습니다.

석션은 잔고장이 많았던 1세대인 에어석션과 2세대인 습식석션, 3세대인 건식석션으로 크게 나누어지며, 1세대인 에어석션은 고장이 많아 사용에 어려움이 있어서 짧은 기간 사용되었었고 이에 반해 습식석션은 가격이 저렴하고 잔고장이 없으며, 소음이 작아 세계적으로 80% 가까이 사용하고 있다.

습식석션은 구조상 흡입력을 만들기 위하여 수도관을 통하여 지속적으로 물이 유입되도록 설계되어 있어서 치과치료 시에 흡입되는 혈액, 고름, 조직 등의 각종 부산물과 압력을 만들기 위한 수돗물이 섞여서 아무런 여과장치 없이 하수구로 흘려 보냄에 따라 2차환경 오염의 문제를 일으키고 있다.

최근 치과치료의 기술이 발전함에 따라 기존 발취나 충치 치료가 대부분이었던 것이 임플란트, 양악수술 등 복잡한 치과치료가 이루어짐에 따라 치료 시에 나오는 의료폐기물 또한 급증하여 세척수의 논란이 커지고 있다.

치과 의료폐기물 관리법은 이미 법제화되어 있으며, 의료폐기물 투기 시 2년 이하의 징역이나 1천만원 이하의 벌금에 처하게 되어 있으며, 의료폐기물은 1톤당 77만 3천원으로 중소형 치과병원이 하루 사용하는 물의 양이 4톤으로만 잡았을 경우 3백만원이 넘는 금액을 지불해야 하며, 월간으로 계산 시 20일 기준 61백만원의 금액을 중소형 치과병원에서 지불하기란 현실적으로 불가능 하다.

실제 국내외 중소형 치과병원에서 하루 방류되는 의료폐기물은 4∼10톤으로 매우 많이 발생하고 있으며 이러한 습식석션 환경오염의 심각성을 인식한 독일 등 유럽 선진국에서는 습식석션 사용을 전면 금지하고 있으며, 이에 대안으로 사용하고 있는 것이 3세대인 건식석션 이다.

제품소개

- 왜 M브레인 컴푸레셔를 사용해야 할까요?

- 하루종일 컴푸레셔에서 나오는 기계실의 오염된 압축공기를 호흡하는 선생님과 스텝의 건강을 생각해 보셨습니니까?

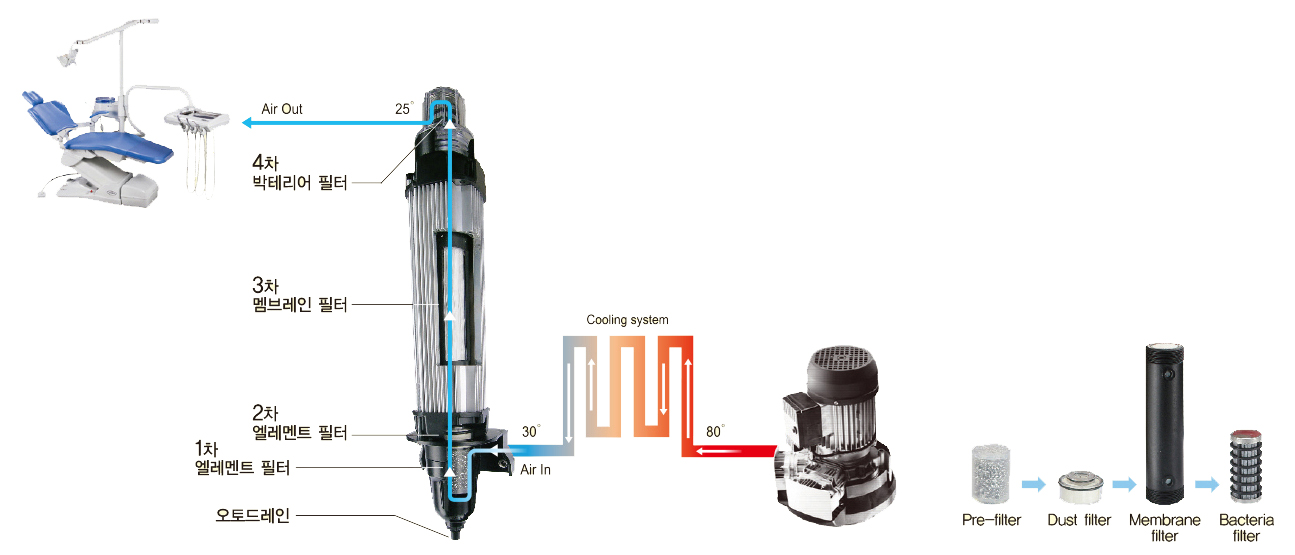

일반 컴푸레셔는 드라이어가 사용되어도 수분/ 미세먼지/ 박테리아 등이 포함된 오염된 공기를 진료실에 공급합니다. - 디메가의 초청정 M브레인 컴프레셔는 이렇게 다릅니다.

- • 국내 유일 치과용 컴푸레셔 수출기업(유럽 품질규격 CE ISO 13485 인증)

• 0.01 micro 사이즈의 미세먼지, 박테리아 제거 (4단계 필터링 시스템)

• 국내 유일 맴브레인 드라이어 장착된 치과용 컴푸레셔 개발

• 핸드피스의 수명 연장

• 100% 완전 건조된 초청정공기 제공

• 초저소음/ 저진동 설계로 편안한 진료환경 제공 - M브레인 드라이어의 구조 및 기능

-

압축공기는 1차 엘레멘트의 스텐레스 메쉬를 통과하면서 물방울들이 서로 결합됩니다.

물방울은 크기가 커지면서 다른 이물질을 모아 밑으로 떨어지면서 오토드레인 집수기로 흘러 모여진 수분은 자동 배출됩니다.

압축공기는 특수면으로 된 2차 엘레멘트로 들어갑니다. 압축공기는 엘레멘트를 통과할 수 있 는 길을 찾기위해 회오리치며 수 많은 작은 소용돌이가 형성됩니다. 미세한 물방울은 분리되어 3차 멤브레인 수중기(H2O)와 같은 상대적으로 투과 속도가 높은 기체는 멤브레인을 빠르게 투과하여 막에서 빠져 나오게 되고 투과 속도가 느린 질소와 산소 같은 기체는 멤브레인을 통과하게 되어 건조한 압축공기는 4차 박테리아 및 수분제로 0.01 미크론 이상의 미세먼지는 제거되어 순수한 에어(Clean Air)만을 체어에 공급합니다.

- 사용목적

- 공기 압축을 통하여 진공 압력을 발생시키는 치과용 건식 석션 장치

- 사용용도

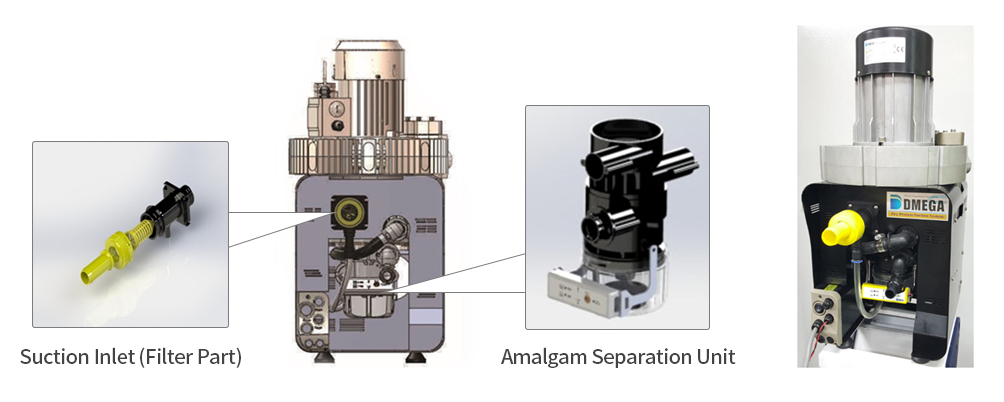

- 진공압을 형성하기 위하여 별도의 물 연결이 필요 없는 Separator 일체형 방식으로 고속 모터에서 형성된 공기의 진공압으로 unit & chair로부터 혈액, 치아 절삭물, 아말감 등을 공기와 완전히 분리하여 잔여 수분, 고형물 등이 하수구로 연결되어 버려지거나 별도의 컨테이너에 보관되도록 한다.

[Mitsubishi 인버터 내장에 의한 1~6 Chair 연결이 가능한 중대형 치과용 Chair Suction Unit]

- 개발배경

- 치아 아말감 폐기물은 물, 혈액과 같은 액체 폐기물과 아말감 금속류의 고체 폐기물이 발생되는 데, 아말감 잔유물은 액체 폐기물에 동시 잔존하여 환경적으로 위해 요소를 가지고 있습니다. 이러한 환경적 문제를 해결하기 위한 진공흡입 방식의 사이클론 필터링을 이용, 아말감을 분리, 수거할 수 있는 Amalgam Separator가 적용된 Megavac 2000A를 개발, 생산하였으며, 본 제품의 성능은 ISO 11143에 기준 아말감 회수율95% 이상의 성능을 유지토록 하였습니다